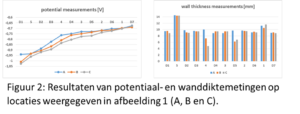

The potential measurements and the microscopic examination showed that stray current corrosion did not play a role in this case. The microbiological investigation confirmed the presence and activity of various corrosion-relevant bacteria and the damage investigation further revealed that these organisms have caused rapid local corrosion, resulting in a regular pattern of holes of different diameter in the quay wall. advised on a strategy that can prevent and counter MIC damage to quay walls. An important component in this is a reliable corrosion monitoring system.

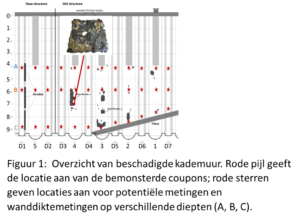

Investigation of a MIC damage case in a sea / brackish water port in the Netherlands. The quay wall consisted of an old section without and a new section with sacrificial anodes. The purpose of the investigation was to find out the cause of the damage to the sheet pile wall in the old part.

For this an extensive analysis package was carried out on the sheet pile:

Such an approach will allow a diagnosis to conclude whether MIC is the cause of the observed damage. Followed by recommendations to mitigate the problem.

Expert Corrosion & Materials

+31 (0) 6 13 96 83 39